Welcome to SHENZHEN?EXCELLENCE?TECHNOLOGY?CO.?,?LTD!

Welcome to SHENZHEN?EXCELLENCE?TECHNOLOGY?CO.?,?LTD!

The introduction

With the rapid development of science and technology, new functions, new concepts and new designs emerge one after another, which makes the electronic products used in our daily life updated at a fast speed. Each product update will require the corresponding material upgrade and change, to adapt to the new requirements. As the representative of electronic products, the mobile phone let us witness the rapid change and the great change. As a mobile phone screen bonding solution, the main is glue and tape. In order to keep up with this rapid development, these materials also need to constantly improve their structure and performance to keep up with the final performance requirements of the product.

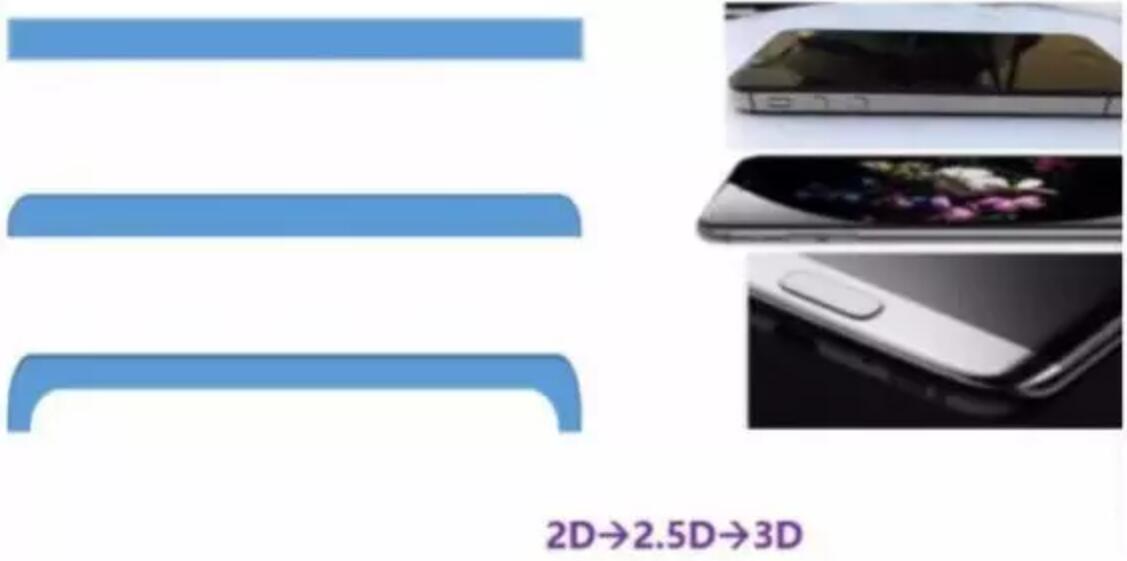

Smartphone screens are not only getting bigger in size, but also in design and structure. Mobile phone screens have changed from 2.4 inches to 6.5 inches, from resistive, capacitive and now OLED screens, all of which show huge changes in mobile phone screens. In appearance, the screen of mobile phone is getting more and more gorgeous, from 2D to 2.5D and then to the present 3D, each progress and change has put forward higher requirements for materials.

As such an important part of human interaction with mobile phone, how to fix and bond it in a beautiful, safe and reliable way and achieve its function is an important issue for the design, manufacturer and material supplier of mobile phone. The following table makes an objective comparison of several main fixation methods used in mobile phone screen fixation.

From the above comparison, we can see that acrylic foam tape has an absolute advantage in screen fixation and is the preferred solution for mobile phone screen fixation. Below we will introduce the design requirements of different mobile phones and the performance characteristics of different tapes.

The role and selection of tape

According to the different roles played by the adhesive tape, the tape can be selected from the following aspects according to the design of the mobile phone and the specific requirements of different mobile phones:

First, high buffer, high waterproof performance requirements:

Because the mobile phone screen is relatively large, the design structure is different, so different models for tape requirements are not the same. For high-end mobile phones, mobile phones themselves in the material design of the components of the requirements are relatively high, then the drop of the tape and waterproof to be relatively high. This needs to play a fixed role of the tape has a good energy absorption, so that it can play a good role in protecting the screen. At the same time also need tape with good waterproof performance. Petran 956 series tape can well meet this performance requirements.

The following table shows the typical performance of the BoChun 956 series:

As can be seen from the table, platinum chun this series of tapes can be comparable to M 86XX series, 59XX series of tapes, in the energy absorption and shock absorption has an absolute advantage, considering from the cost performance, is a rare good product when this type of machine design.

Two, high waterproof, high drop resistance and anti warping performance requirements

Some mobile phone due to the limitation of design and the material itself, local has certain tolerance, this need to tape in a binder Can strong adhesive ability, will screen and casing tightly together to make up the lack of design and manufacturing defects, may also need to tape has a certain ability to resist to launch prevents deformation of the parts when in actual use stress, etc. In this case, platinum chun 958 series tape can play a better role, to meet the basic performance of mobile phone design needs.

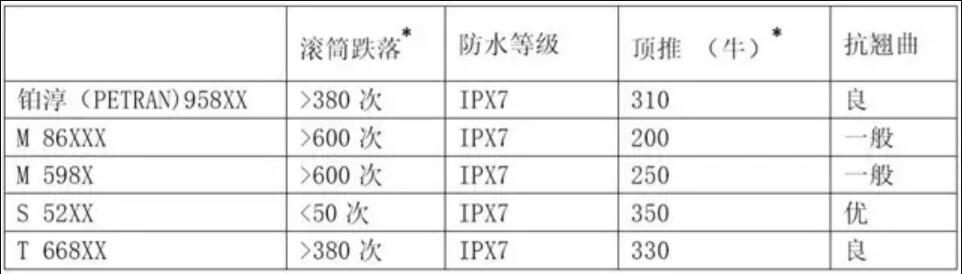

The following table shows the typical performance of the BoChun 958 series:

The warpage resistance and thrust performance of this series of tapes are almost as good as the S 52XX, while providing superior impact resistance.

Three, high waterproof, strong bonding performance requirements

Also has a lot of mobile phones on the market due to the structure, design and positioning, and other aspects to consider, not only need to tape can quickly fastened to the screen, and to have higher resistance to launch power, so as to realize the strong bond of tape on the screen, platinum chun 965 series tape can be a very good solve this problem, and meet the demand of mobile phone design and engineer.

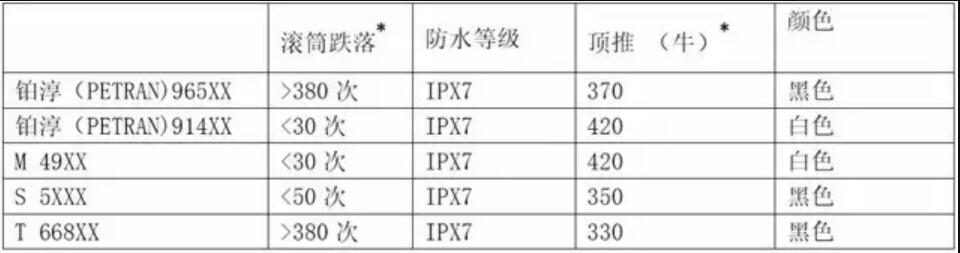

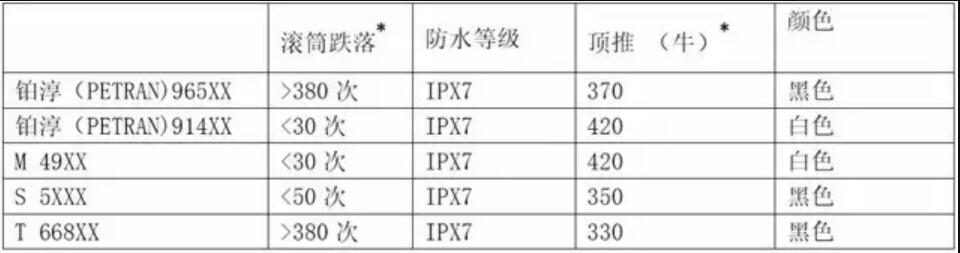

The following table is a typical performance comparison of the PlatChun 965 series:

In terms of jacking force, this series of belts of BoChun can perfectly replace M's 49XX and other products with high jacking force, so as to meet the requirements of this kind of design.

IV. General-purpose and cost-effective demand

Some mobile phones in the design of various performance requirements are more balanced, hoping to achieve a relatively high cost performance, at the same time has a good operability, in this respect, Platinum Chun also has a 58XXX series of tape specially to meet these requirements.

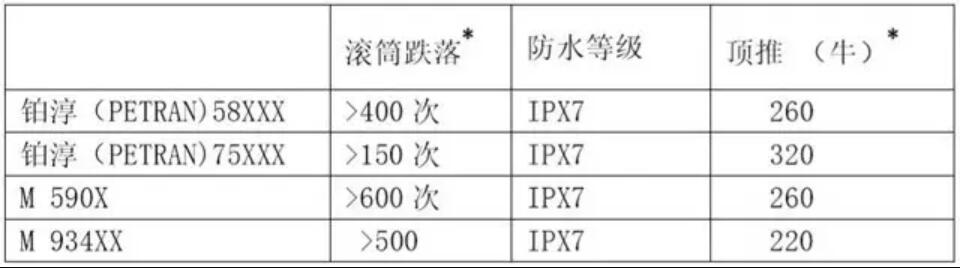

The following table is the typical performance of PlatChun 58XXX series tape:

5. Solutions to improve die cutting yield and narrow frame of mobile phone

With the rapid development of the mobile phone industry, as mentioned above, mobile phones need not only practical functions but also visual beauty. 3D, narrow frame and other designs have emerged as The Times require. How to solve the tape die-cutting yield and achieve the narrow frame bonding of mobile phone screen is a new development direction of the new requirements for tape. Shanghai platinum chun relying on their own research and development strength and the understanding of the market, by changing the above series of products structure effectively solves the die cutting and narrow bezel design requirements, and achieved good effect in practical application, fully shows the platinum's research and development strength and ability to solve problems quickly, and very good to satisfy the customer's requirements.

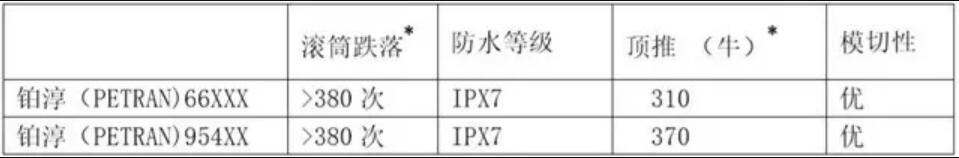

This series of products includes 66 series and 954 series. Typical performance is as follows:

Through the above comparison of different design requirements, it is not difficult to find that the two series of tapes have greatly improved the die-cutting performance while maintaining the performance of the original acrylic foam tape in falling, pushing, warping and other aspects. It can realize the die-cutting of the narrow frame below 0.6 mm, and maintain a good die-cutting yield. The application of acrylic foam tape in mobile phone screen has reached the leading level in the industry, and has been successfully used in international well-known enterprises.

Customized product production and quick response ability

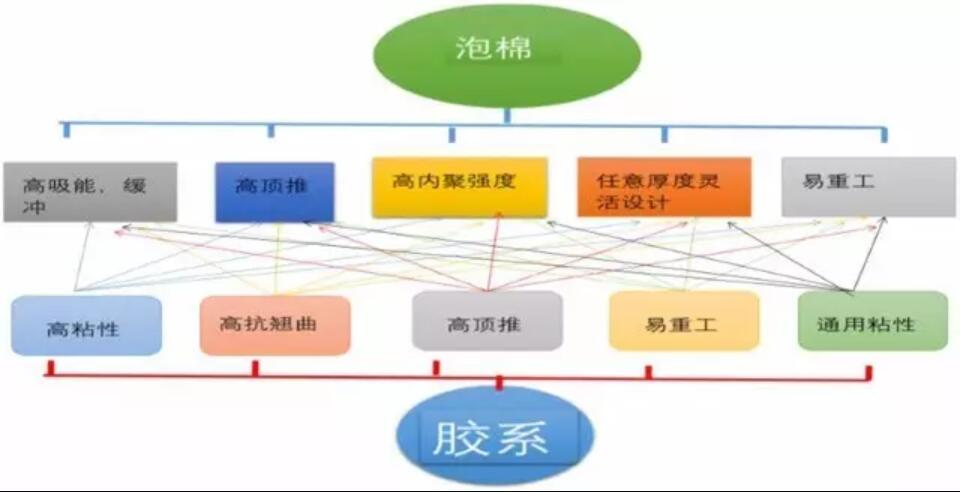

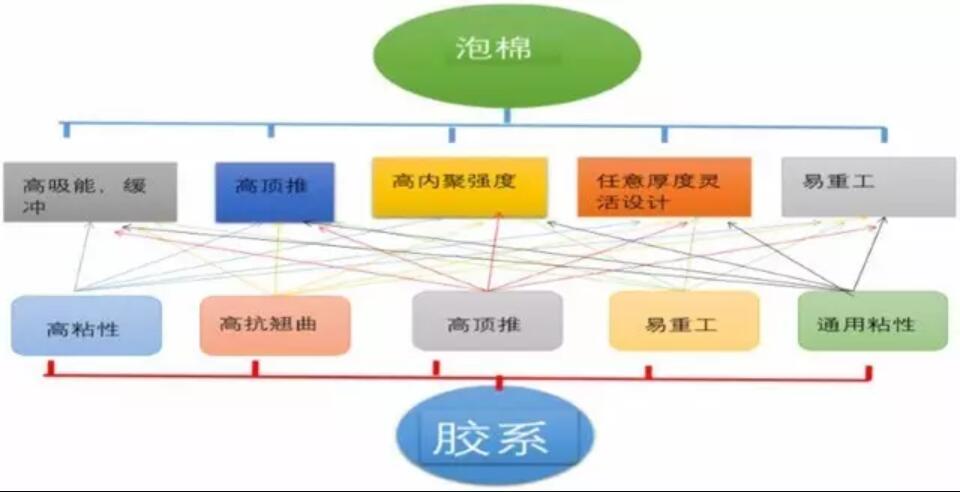

As mentioned above, electronic products are developing and changing at a fast pace, which requires us to adapt to new design requirements quickly and respond quickly. Shanghai Bochun Adhesives Technology has a strong product accumulation and product research and development experience, in the mobile phone frame bonding program experience, our foam can be realized, high drop resistance and energy absorption, high cohesion, high top push, from 0.1 mm to 0.5 mm of arbitrary thickness design. At the same time, our adhesive system can also achieve universal bonding to various substrates, warpage resistance bonding, easy to heavy work and high peeling force, etc. The combination of core and different rubber system enables us to respond to customers' needs in the shortest time, provide the products needed to solve customers' problems, truly realize the rapid design and solution of product solutions, adapt to the current product update speed to the material requirements, improve the efficiency and achieve a win-win situation for the customers.

The quick response mode of the product is shown in the figure below, which provides a strong guarantee for our quick response and enables rapid customized production of the product:

New opportunities

New technologies and requirements such as OLED, ultra-thin, waterproof, 5G, wireless charging, and WiFi charging are driving the huge transformation of mobile phones, while putting forward more demanding requirements for new materials. The previous metal back cover may hinder the development of this new technology, now glass back cover and ceramic back cover have been widely adopted and developed with the advent of the new technology. However, due to the processing technology of glass and ceramic itself is complicated and the characteristics of the material itself, a lot of mobile phone design challenges, how to overcome the manufacturing tolerance and can have perfect binding and waterproof is the acrylic foam tape has a new challenge, platinum chun has used its own products and technology advantages to a good solution of this problem, We are willing to constantly improve ourselves in the face of new opportunities, and are willing to work together with friends in the mobile phone industry chain to always keep up with the pace of product innovation, to achieve the innovation of new materials.

conclusion

In the market today, globalization and new applications require the multiplexes, customization, rapid response, high cost performance and continual research innovation is the new requirements for materials, acrylic foam tape in the past has proven to be solve bonding screen mobile phone change better options, some of its features is PE foam can't replace. The acrylic foam tape of Bochun Adhesives Co., Ltd. has been proved and applied in the bonding of front and rear covers of mobile phones, and has achieved good results. We will also continue to rely on its acrylic foam good technical advantages and product reputation to constantly promote the acrylic foam tape in the mobile phone screen to improve, update.